Products »

Powder Metallurgical High Speed Steels

HG 3344 (1.3344,DIN S5-5-3,ASP23,AISI M3:2)

1) Chemical Composition and its permissible allowance as per DIN EN ISO4957: %

| C | Mn | Si | P | S | Cr | Mo | V | W | Co |

| 1.15- 1.25 | ≤0.40 | ≤0.45 | ≤0.03 | ≤0.03 | 3.80-4.50 | 4.70-5.20 | 2.70-3.20 | 6.00-6.70 | ≤0.50 |

| +/- 0.04 | +/- 0.04 | +/- 0.03 | +/- 0.005 | +/- 0.005 | +/- 0.10 | +/- 0.10 | +/- 0.10 | +/- 0.15 | +/- 0.10 |

2) Application

Milling cutters, broach needles, cutting and punching, tools, dies, working rolls for cluster rolling stand.

3) Size range

| Hot rolled, mm | Forged, mm | Tolerance | |

| Round | Dia6-Dia90 XRL | Dia80-Dia503X RL | EN10060 for hot rolled;DIN7527/6 for forged black;

En10278 H9 or H11 for peeled round; +3mm/-0 for forged turned |

| Flat & block | 6-90X60-805XRL | 90-450X90-610XRL | EN10058 for hot rolled;+5mm/-0 in thickness and +15/-0 in width for forged black;

+3mm/-0 in thickness and +10/-0 in width for forged black for Forged milled |

4) Forging

Pre heat slowly and uniformly to 850-900°C. The heat should then be increased more quickly to the forging temperature of 1050-1150°C. If during the forging the temperature of the material drops below 880-900°C, re heating will be necessary. Cool the component very slowly after forging.

5) Heat treatment

Annealing

Heat to 850-990°C, cool slowly. This will produce a maximum Brinell hardness of 240-300.

Stress Relieving

Stress relieving to remove machining stresses should be carried out by heating to 650°C, holding for one hour at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening

Heat up to 450-500°C, then preheat to 850-900°C. Harden from a temperature of 1140-1180°C followed by inert gas quenching or warm bath 550°C. Hardness after quenching is min. 64 HRC.

Tempering

Tempering temperature: Min. 3 x 1.5 hour at 560°C.

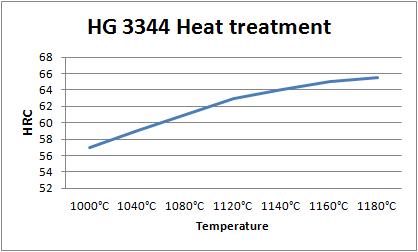

Hardening Temperature (°C) vs. Hardness (HRC)

| Temperature | 1000°C | 1040°C | 1080°C | 1120°C | 1140°C | 1160°C | 1180°C |

| HRC | 57 | 59 | 61 | 63 | 64 | 65 | 65.5 |

HG ASP2030 (M36, ASP2030)

1) Chemical Composition and its permissible allowance as per DIN EN ISO4957: %

| C | Mn | Si | P | S | Cr | Mo | V | W | Co |

| 1.25- 1.35 | ≤0.40 | ≤0.45 | ≤0.03 | ≤0.03 | 3.80- 4.50 | 4.70- 5.20 | 2.70- 3.20 | 6.00- 6.70 | 8.10- 8.80 |

| +/- 0.04 | +/- 0.04 | +/- 0.03 | +/- 0.005 | +/- 0.005 | +/- 0.10 | +/- 0.10 | +/- 0.10 | +/- 0.15 | +/- 0.15 |

2) Application

Typical applications this high speed steel grade are twist drills, reamers, broaching tools, taps, milling tools, metal saws.

3) Size range

| Hot rolled, mm | Forged, mm | Tolerance | |

| Round | Dia6-Dia90 XRL | Dia80-Dia503X RL | EN10060 for hot rolled;DIN7527/6 for forged black;

En10278 H9 or H11 for peeled round; +3mm/-0 for forged turned |

| Flat & block | 6-90X60-805XRL | 90-450X90-610XRL | EN10058 for hot rolled;+5mm/-0 in thickness and +15/-0 in width for forged black;

+3mm/-0 in thickness and +10/-0 in width for forged black for Forged milled |

4) Forging

Pre heat slowly and uniformly to 850-900°C. The heat should then be increased more quickly to the forging temperature of 1050-1150°C. If during the forging the temperature of the material drops below 880-900°C, re heating will be necessary. Cool the component very slowly after forging.

5) Heat treatment

Annealing

Annealing is recommended after hot working and before re hardening. The annealed hardness achieved should be 285HB or lower.

Stress Relieving

Stress relieving to remove machining stresses should be carried out by heating to 650°C, holding for one hour at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening

To harden at 1210-1230°C , by oil. Its hardness can reach Min HRC66.

Tempering

Temper the steel immediately after quenching, tempering at 550-570°C.

HG ASP2060 (1.3241, ASP2060)

1) Chemical Composition and its permissible allowance as per DIN EN ISO4957: %

| C | Mn | Si | P | S | Cr | Mo | V | W | Co |

| 2.15-2.45 | ≤0.40 | ≤0.45 | ≤0.03 | ≤0.03 | 3.80-4.50 | 6.70-7.30 | 6.20-6.80 | 6.00-6.80 | 10.10-10.80 |

2) Application

Cold working tooling, blanking thin, electronic packaging materials

3) Size range

| Hot rolled, mm | Forged, mm | Tolerance | |

| Round | Dia6-Dia90 XRL | Dia80-Dia503X RL | EN10060 for hot rolled;DIN7527/6 for forged black;

En10278 H9 or H11 for peeled round; +3mm/-0 for forged turned |

| Flat & block | 6-90X60-805XRL | 90-450X90-610XRL | EN10058 for hot rolled;+5mm/-0 in thickness and +15/-0 in width for forged black;

+3mm/-0 in thickness and +10/-0 in width for forged black for Forged milled |

4) Forging

Pre heat slowly and uniformly to 850-900°C. The heat should then be increased more quickly to the forging temperature of 1050-1150°C. Cool the component very slowly after forging.

5) Heat treatment

Annealing

To heat up 850-900°C. The annealed hardness achieved should be 340HB or lower.

Stress Relieving

After rough machining, tool should be heat up to 600-700°C, hold for two hours, slow cooling to 500°C, then cooling in the air.

Hardening

To harden at 1210-1230°C , by oil. Its hardness can reach Min HRC66.

Tempering

Temper the steel immediately after quenching, tempering at 550-570°C.

HG 3202 (1.3202, DIN S12-1-4-5, ASP15, AISI T15)

1) Chemical Composition and its permissible allowance as per DIN EN ISO4957: %

| C | Mn | Si | P | S | Cr | Mo | V | W | Co |

| 1.50- 1.60 | 0.15- 0.40 | 0.15- 0.40 | ≤0.03 | ≤0.03 | 3.75- 5.00 | ≤1.00 | 4.50- 5.25 | 11.75- 13.00 | 4.75- 5.25 |

| +/- 0.05 | +/- 0.04 | +/- 0.03 | +/- 0.005 | +/- 0.005 | +/- 0.10 | +/- 0.05 | +/- 0.10 | +/- 0.20 | +/- 0.15 |

2) Application

High speed steel, for heavy-duty operations. Turning knives, milling cutters for rough machining, smoothing.

3) Size range

| Hot rolled, mm | Forged, mm | Tolerance | |

| Round | Dia6-Dia90 XRL | Dia80-Dia503X RL | EN10060 for hot rolled;DIN7527/6 for forged black;

En10278 H9 or H11 for peeled round; +3mm/-0 for forged turned |

| Flat & block | 6-90X60-805XRL | 90-450X90-610XRL | EN10058 for hot rolled;+5mm/-0 in thickness and +15/-0 in width for forged black;

+3mm/-0 in thickness and +10/-0 in width for forged black for Forged milled |

4) Forging

The forging temperature is 900-1100°C. If during the forging the temperature of the material drops below 880-900°C, re-heating will be necessary. Cool the component very slowly after forging.

5) Heat treatment

Annealing

Heat to 820-860°C, cool slowly in furnace. This will produce a maximum Brinell hardness of 280.

Stress Relieving

Stress relieving to remove machining stresses should be carried out by heating to 600-650°C, holding for one hour at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening

1st pre-heating: 400°C. 2nd and 3rd pre-heating: 850°C and 850°C and 1050°C. Harden from a temperature of 1190-1240°C followed by oil or air quenching or warm bath approx. 550°C/air.

Tempering

Tempering temperature: 3 x at 540-580°C. Hardness after tempering is 65-67 HRC.

HG 3343 (DIN 1.3343, AISI M2)

1) Chemical Composition and its permissible allowance as per DIN EN ISO4957: %

| C | Mn | Si | P | S | Cr | Mo | V | W | Co |

| 0.78- 0.88 | ≤0.40 | ≤0.45 | ≤0.03 | ≤0.03 | 3.80- 4.50 | 4.70- 5.20 | 1.70- 2.10 | 5.90- 6.70 | ≤0.50 |

| +/- 0.05 | +/- 0.04 | +/- 0.03 | +/- 0.005 | +/- 0.005 | +/- 0.15 | +/- 0.15 | +/- 0.15 | +/- 0.15 | +/- 0.15 |

2) Application

Typical applications this high speed steel grade are twist drills, reamers, broaching tools, taps, milling tools, metal saws. 1.3343 is suitable for cold forming tools such as extrusion rams and dies, also cutting tools and plastic moulds with elevated wear resistance.

3) Size range

| Hot rolled, mm | Forged, mm | Tolerance | |

| Round | Dia6-Dia90 XRL | Dia80-Dia503X RL | EN10060 for hot rolled;DIN7527/6 for forged black;

En10278 H9 or H11 for peeled round; +3mm/-0 for forged turned |

| Flat & block | 6-90X60-805XRL | 90-450X90-610XRL | EN10058 for hot rolled;+5mm/-0 in thickness and +15/-0 in width for forged black;

+3mm/-0 in thickness and +10/-0 in width for forged black for Forged milled |

4) Forging

Pre heat slowly and uniformly to 850-900°C. The heat should then be increased more quickly to the forging temperature of 1050-1150°C. If during the forging the temperature of the material drops below 880-900°C, re heating will be necessary. Cool the component very slowly after forging.

5) Heat treatment

Annealing

Annealing is recommended after hot working and before re hardening. Heat to 850°C at a rate of no more than 220°C per hour. Always hold at temperature for one hour per 25mm of thickness (with two hours being minimum). Furnace cool slowly. The annealed hardness achieved should be 255HB or lower.

Stress Relieving

If tools are heavily machined or ground it is recommended to stress relieve after machining and prior to hardening to minimise the possibility of distortion. To stress relieve heat the component to 675-725°C and soak well (approx 2 hours), then cool in air. The 1.3343 tools can be finish machined before heat treatment.

Hardening

Pre heat the component in two steps; 450-500°C then 850-900°C. Continue heating to the final hardening temperature of 1200-1250°C and ensure that the component is heated through. Care must be taken to not allow the component to remain too long at the hardening temperature. Quench in warm oil or salt. If quenching in salt allow the tools to equalize, then complete the quench in air. If quenching in oil remove the component from the oil at about 560°C and then air cool. 1.3343 high speed steel is also suitable for vacuum hardening. Its hardness can reach max HRC64.

Tempering

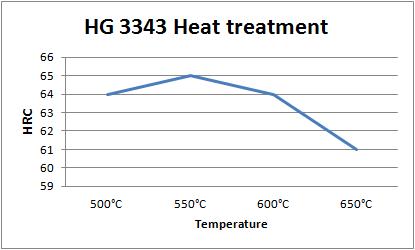

Temper the steel immediately after quenching. Heat uniformly and carefully to the selected tempering temperature and hold at for at least two hours (one hour per 25mm of total thickness). Double tempering is essential and for tools cut by wire EDM triple tempering is strongly recommended. Hardness after hardening and tempering is as following table:

| Temperature | 500°C | 550°C | 600°C | 650°C |

| HRC | 64 | 65 | 64 | 61 |

HG 3243 (DIN 1.3243, AISI M35)

1) Chemical Composition and its permissible allowance as per DIN EN ISO4957: %

| C | Mn | Si | P | S | Cr | Mo | V | W | Co |

| 0.87- 0.95 | ≤0.40 | ≤0.45 | ≤0.03 | ≤0.03 | 3.80- 4.50 | 4.70- 5.20 | 1.70- 2.10 | 5.90- 6.70 | 4.50- 5.00 |

| +/- 0.03 | +/- 0.04 | +/- 0.03 | +/- 0.005 | +/- 0.005 | +/- 0.10 | +/- 0.10 | +/- 0.07 | +/- 0.10 | +/- 0.10 |

2) Application

Used in conditions where the demand for hot hardness is important. It is also a good quality wear resistant grade for cold work applications. Commonly used for cutting tools including broaches, end mills, bandsaw blades, milling cutters, reamers and cold work tools.

3) Size range

| Hot rolled, mm | Forged, mm | Tolerance | |

| Round | Dia6-Dia90 XRL | Dia80-Dia503X RL | EN10060 for hot rolled;DIN7527/6 for forged black;

En10278 H9 or H11 for peeled round; +3mm/-0 for forged turned |

| Flat & block | 6-90X60-805XRL | 90-450X90-610XRL | EN10058 for hot rolled;+5mm/-0 in thickness and +15/-0 in width for forged black;

+3mm/-0 in thickness and +10/-0 in width for forged black for Forged milled |

4) Forging

Pre heat steel slowly and uniformly to 450°-500°C and equalise. Then increase more quickly to the forging temperature of 950°-1100°C and equalise prior to forging. Do not allow the forging temperature to drop below 950°C, if this occurs re heating will be necessary. Always cool the steel very slowly after forging.

5) Heat treatment

Annealing

Annealing 1.3243 is recommended after hot working and before re hardening. Heat the steel to 850°C at a rate of no more than 220°C per hour. Always hold at temperature for one hour per 25mm of thickness (with two hours being minimum). Furnace cool slowly. The annealed hardness achieved should be 269 HB or lower.

Stress Relieving

If tools produced from 1.3243 are heavily machined or ground it is recommended to stress relieve after machining and prior to hardening to minimise the possibility of distortion. To stress relieve heat the component to 600-700°C and soak well (approx 2 hours) Cool slowly in the furnace. The tools can be finish machined before heat treatment.

Hardening

For best results harden the steel in a vacuum or atmosphere furnace, or in a properly rectified salt bath. Pre heat thoroughly in two steps to 450-500°C, then to 820-870°C, transfer to the high temperature salt bath or furnace. The exact hardening temperature to use for 1.3243 will depend on the type of work being treated, but in general components should be hardened from the range of 1050-1250°C. Its hardness can reach 64HRC.

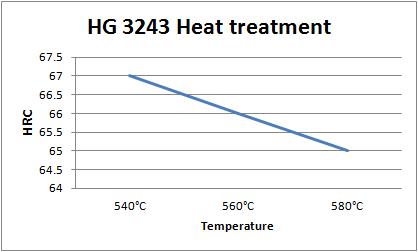

Tempering

Temper 1.3243 between 510-620°C. Triple tempering is recommended with a minimum of two hours at temperature per cycle. The component should be cooled in still air to room temperature between tempering treatments. Hardness after hardening and tempering is as following table:

| Temperature | 540°C | 560°C | 580°C |

| HRC | 67 | 66 | 65 |

HG 3247 (DIN 1.3247, AISI M42)

1) Chemical Composition and its permissible allowance as per DIN EN ISO4957: %

| C | Mn | Si | P | S | Cr | Mo | V | W | Co |

| 1.05- 1.15 | ≤0.40 | ≤0.70 | ≤0.03 | ≤0.03 | 3.50- 4.50 | 9.00- 10.00 | 0.90- 1.30 | 1.20- 1.90 | 7.50- 8.50 |

| +/- 0.03 | +/- 0.04 | +/- 0.03 | +/- 0.005 | +/- 0.005 | +/- 0.10 | +/- 0.10 | +/- 0.10 | +/- 0.07 | +/- 0.15 |

2) Application

1.3247 high speed steel can be used in conditions where the demand for hot hardness is important. It is suitable for cutting tools including twist drills, taps, broaches tools, milling cutters, reamers, end mills, bandsaws and cold work tools.

3) Size range

| Hot rolled, mm | Forged, mm | Tolerance | |

| Round | Dia6-Dia90 XRL | Dia80-Dia503X RL | EN10060 for hot rolled;DIN7527/6 for forged black;

En10278 H9 or H11 for peeled round; +3mm/-0 for forged turned |

| Flat & block | 6-90X60-805XRL | 90-450X90-610XRL | EN10058 for hot rolled;+5mm/-0 in thickness and +15/-0 in width for forged black;

+3mm/-0 in thickness and +10/-0 in width for forged black for Forged milled |

4) Forging

Pre heat the steel slowly and uniformly to 650-760°C and equalise. Then increase more quickly to the forging temperature of 1010-1150°C and equalise prior to forging. Do not allow the forging temperature to drop below 980°C, if this occurs re heating will be necessary. Always cool the high speed steel very slowly after forging.

5) Heat treatment

Annealing

Annealing is recommended after hot working and before re hardening. Heat the steel to 850°C at a rate of no more than 220°C per hour. Always hold at temperature for one hour per 25mm of thickness (with two hours being minimum). Furnace cool slowly. The annealed hardness achieved should be 269 Brinell or lower.

Stress Relieving

If tools produced from 1.3247 high speed steel are heavily machined or ground it is recommended to stress relieve after machining and prior to hardening to minimise the possibility of distortion. To stress relieve heat the component to 600-650°C and soak well (approximately two hours) Cool slowly in the furnace. The 1.3247 tools can be finish machined before heat treatment.

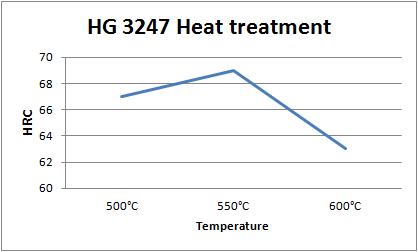

Hardening

For best results harden the 1.3247 in a vacuum or atmosphere furnace, or in a properly rectified salt bath. Pre heat thoroughly to 820-870°C, transfer to the high temperature salt bath or furnace. The exact hardening temperature to use will depend on the type of work being treated, but in general components should be hardened from the range of 1160-1180°C in salt, or 1180-1190°C in atmosphere or vacuum furnaces. After a short hold at the hardening temperature, quench the component without further soaking into salt at 540-595°C or warm oil. If salt quenched allow the component to equalise at the bath temperature and then complete the quench in still air.

| Temperature | 500°C | 550°C | 600°C |

| HRC | 67 | 69 | 63 |