Products »

Structure Steels

HG 4130 (DIN 1.7218, AISI 4130, JIS SCM420)

1) Chemical Composition and its permissible allowance as per DIN EN ISO4957: %

| C | Mn | Si | P | S | Cr | Mo |

| 0.22-0.29 | 0.60-0.90 | ≤0.40 | ≤0.035 | ≤0.035 | 0.90-1.20 | 0.15-0.30 |

| +/-0.02 | +/-0.04 | +/-0.03 | +/-0.005 | +/-0.005 | +/-0.10 | +/-0.03 |

2) Application

AISI 4130 is widely used for a variety of applications in the oil and gas sector. Typical applications include components such as valve bodies, pumps and fittings.

3) Size range

| Hot rolled, mm | Forged, mm | Tolerance | |

| Round | Dia6-Dia90 XRL | Dia80-Dia503X RL | EN10060 for hot rolled; DIN7527/6 for forged black; En10278 H9 or H11 for peeled round; +3mm/-0 for forged turned |

| Flat & block | 6-90X60-805XRL | 90-450X90-610XRL | EN10058 for hot rolled; +5mm/-0 in thickness and +15/-0 in width for forged black; +3mm/-0 in thickness and +10/-0 in width for forged black for Forged milled |

4) Forging

Preheat carefully, then raise temperature to 950-1200°C for forging. Do not forge below 950°C.

5) Heat treatment

Annealing

Heat the AISI 4130 slowly to 850°C and allow enough time for the steel to be thoroughly heated. Cool slowly in the furnace to 480°C followed by air cooling.

hot rolled, normalized with hardness of 249 HB Max.

Stress Relieving

When parts are heavily machined, ground or otherwise subject to cold work, stress relieving will be beneficial prior to any hardening.

Hardening

AISI 4130 steel is usually supplied ready heat treated with a hardness of 18-22HRC. If further heat treatment is required annealed AISI 4130 should be heated slowly to 870-890°C and after adequate soaking at this temperature quench in oil. Temper as soon as tools reach room temperature.

Tempering

Heat carefully to a suitable temperature selected by reference to a tempering chart or table (usually between 400-570°C, soak at the temperature for 2 hours per 25mm of ruling section, then all to cool in the air. Tempering between 250-375°C is not advised as tempering within this range will seriously reduce the impact value.

6) Mechanical properties

(Determined on quenched (880°С+/-15°С, oil) and tempered (540°С +/-15°С, air)

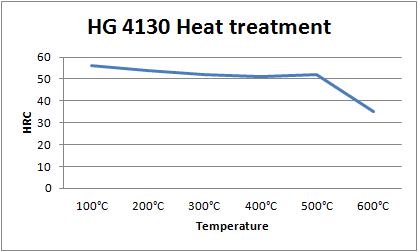

| Temperature | 100°C | 200°C | 300°C | 400°C | 500°C | 600°C |

| HRC | 56 | 54 | 52 | 51 | 52 | 35 |

HG 4140 (DIN 1.7225, AISI 4140, JIS SCM440)

1) Chemical Composition and its permissible allowance as per DIN EN ISO4957: %

| C | Mn | Si | P | S | Cr | Mo |

| 0.38-0.45 | 0.60-0.90 | ≤0.40 | ≤0.035 | ≤0.035 | 0.90-1.20 | 0.15-0.30 |

| +/-0.02 | +/-0.04 | +/-0.03 | +/-0.005 | +/-0.005 | +/-0.05 | +/-0.03 |

2) Application

AISI 4140 is commonly used for a variety of applications in the oil and gas sector. Typical applications include components such as connection rods, collets, conveyor pins, gears, stem assemblies, pump shafts and tool holders.

3) Size range

| Hot rolled, mm | Forged, mm | Tolerance | |

| Round | Dia6-Dia90 XRL | Dia80-Dia503X RL | EN10060 for hot rolled; DIN7527/6 for forged black; En10278 H9 or H11 for peeled round; +3mm/-0 for forged turned |

| Flat & block | 6-90X60-805XRL | 90-450X90-610XRL | EN10058 for hot rolled; +5mm/-0 in thickness and +15/-0 in width for forged black; +3mm/-0 in thickness and +10/-0 in width for forged black for Forged milled |

4) Forging

Preheat the steel carefully, then raise the temperature to 1150-1200°C for forging. Do not forge below 850°C.

5) Heat treatment

Annealing

Heat the AISI 4140 slowly to 800-850°C and allow enough time for the steel to be thoroughly heated. Cool slowly in the furnace to 480°C followed by air cooling. It can reach max HB241.

Stress Relieving

When parts are heavily machined, ground or otherwise subject to cold work, stress relieving will be beneficial prior to hardening.

Hardening

AISI 4140 steel is usually supplied ready heat treated to 18-22HRC. If further heat treatment is required annealed AISI 4140 should be heated slowly to 840-875°C and after adequate soaking at this temperature quench in oil. Temper as soon as the tools reach room temperature.

Tempering

Heat the AISI 4140 carefully to a suitable temperature selected by reference to a tempering chart or table (usually between 550-700°C, soak at the temperature for 2 hours per 25mm of ruling section, then allow to cool in air. Tempering between 250-375°C is not advised as tempering within this range will seriously reduce the impact value.

HG 6511(DIN 1.6511, AISI 4340)

1) Chemical Composition and its permissible allowance as per DIN EN ISO4957: %

| C | Mn | Si | P | S | Cr | Mo | Ni |

| 0.32-0.40 | 0.50-0.80 | ≤0.40 | ≤0.035 | ≤0.035 | 0.90-1.20 | 0.15-0.30 | 0.90-1.20 |

| +/-0.03 | +/-0.04 | +/-0.03 | +/-0.005 | +/-0.005 | +/-0.05 | +/-0.04 | ≤0.05 |

2) Application

Typical applications are for structural use, such as aircraft landing gear, power transmission gears and shafts and other structural parts, general engineering parts, connecting rods and bolts, gun barrels.

3) Size range

| Hot rolled, mm | Forged, mm | Tolerance | |

| Round | Dia6-Dia90 XRL | Dia80-Dia503X RL | EN10060 for hot rolled; DIN7527/6 for forged black; En10278 H9 or H11 for peeled round; +3mm/-0 for forged turned |

| Flat & block | 6-90X60-805XRL | 90-450X90-610XRL | EN10058 for hot rolled; +5mm/-0 in thickness and +15/-0 in width for forged black; +3mm/-0 in thickness and +10/-0 in width for forged black for Forged milled |

4) Forging

Hot forming temperature: 1050-850°C.

5) Heat treatment

Normalizing

Temperature: 850-880°C.

Soft Annealing

Heat to 650-700°C, cool slowly. This will produce a maximum Brinell hardness of 248.

Stress Relieving

Stress relieving to remove machining stresses should be carried out by heating to approx. 650°C, holding for 1-2 hours at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening

Harden from a temperature of 830-860°C followed by oil quenching.

Tempering

Tempering temperature: 540-680°C.

Mechanical Properties in Hardening and Tempering Condition

| Diameter (mm) | 0.2 % proof stress (N/mm2) | Tensile strength (N/mm2) | Elongation (%) | Reduction of area (%) | Notch impact energy (J) |

| <16 | 900 | 1100-1300 | 10 | 45 | 40 |

| 17-40 | 800 | 1000-1200 | 11 | 50 | 45 |

| 41-100 | 700 | 900-1100 | 12 | 55 | 50 |

| 101-160 | 600 | 800-950 | 13 | 60 | 50 |

| 161-250 | 550 | 750-900 | 14 | 60 | 50 |

HG 2316 (DIN 1.2316, X38CrMo16)

1) Chemical Composition and its permissible allowance as per DIN EN ISO4957: %

| C | Mn | Si | P | S | Cr | Mo | Ni |

| 0.33-0.45 | ≤1.50 | ≤1.00 | ≤0.03 | ≤0.03 | 15.50-17.50 | 0.80-1.30 | ≤1.00 |

| +/-0.03 | +/-0.04 | +/-0.03 | +/-0.005 | +/-0.005 | +/-0. 15 | +/-0.05 | +/-0.05 |

2) Application

Moulds for chemically aggressive plastics and plastics containing abrasive fillers, slit dies, profile dies, drop forging tools, blowing moulds, mould inserts, moulds and extruding tools for corrosively acting plastics such as PVC amino plastics and similar materials.

3) Size range

| Hot rolled, mm | Forged, mm | Tolerance | |

| Round | Dia6-Dia90 XRL | Dia80-Dia503X RL | EN10060 for hot rolled; DIN7527/6 for forged black; En10278 H9 or H11 for peeled round; +3mm/-0 for forged turned |

| Flat & block | 6-90X60-805XRL | 90-450X90-610XRL | EN10058 for hot rolled; +5mm/-0 in thickness and +15/-0 in width for forged black; +3mm/-0 in thickness and +10/-0 in width for forged black for Forged milled |

4) Forging

Forging temperate at 900-1100°C, after forging, cool very slowly.

5) Heat treatment

Annealing

Heat uniformly to 780-820°C. Soak well, cool slowly in the furnace. It can reach maximum hardness of HB285.

Stress Relieving

When dies are heavily machined, we recommend stress relieving just before finish machining in order to relieve machining strains. Heat to 460-500°C. Soak well and allow cooling in the air.

Hardening

Heat uniformly to 1010°C until heated through. Quench in oil, it can reach hardness of 48-52HRC.

Tempering

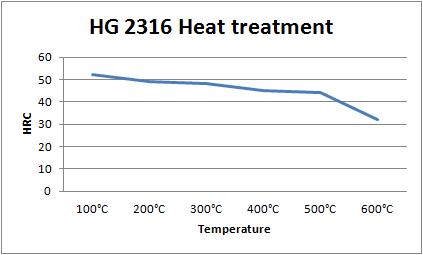

Heat uniformly and soak at the tempering temperature 580°C for at least one hour per 25mm of section. Hardness after hardening and tempering is as following table:

| Temperature | 100°C | 200°C | 300°C | 400°C | 500°C | 600°C |

| HRC | 52 | 49 | 48 | 45 | 44 | 32 |